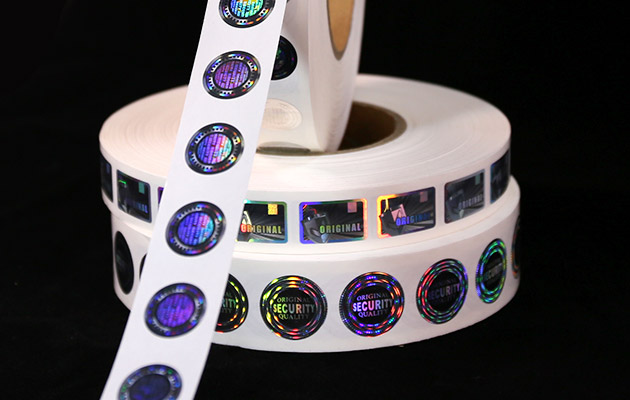

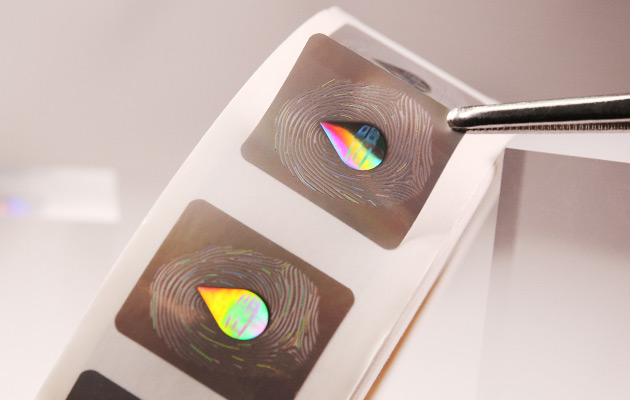

Holographic stickers are no longer just decorative; they are also functional. They have become an essential tool for brand protection and consumer trust. From food and cosmetics to electronics and luxury goods, custom holographic stickers are now widely used across industries.

For businesses, a well-designed holographic sticker not only protects against counterfeit products but also strengthens brand image and competitiveness. So, how does custom sticker production work, and what pitfalls should you avoid? Let’s explore step by step.

I. Core Steps in Custom Holographic Sticker Production

1. Define Your Anti-Counterfeit Requirements

First, clarify your needs:

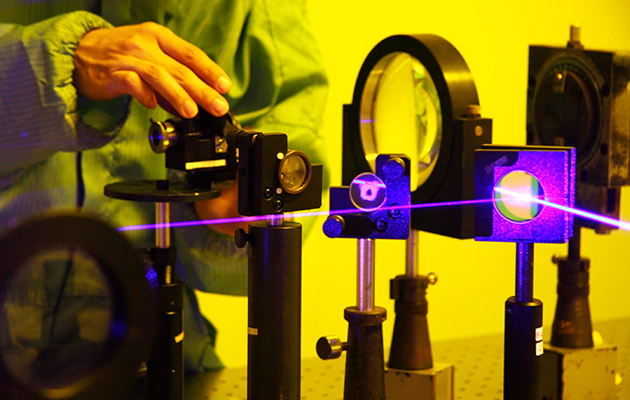

- Security Level: Optical anti-counterfeiting is based on nano-scale microstructures that create unique color, motion, and 3D effects. You can choose first-, second, or third-level security solutions depending on your product.

- Application Surface: Stickers must adhere to different materials such as plastic, glass, metal, or paper. Each requires specific adhesives to ensure durability.

- Additional Features: Options include tamper-evident functions (VOID, honeycomb, fragile paper), anti-transfer technology, and digital traceability via QR codes or serial numbers

2. Verify Manufacturer Credentials

Next, choose a qualified partner. The foundation of anti-counterfeiting is non-replicability, so strong expertise is crucial.

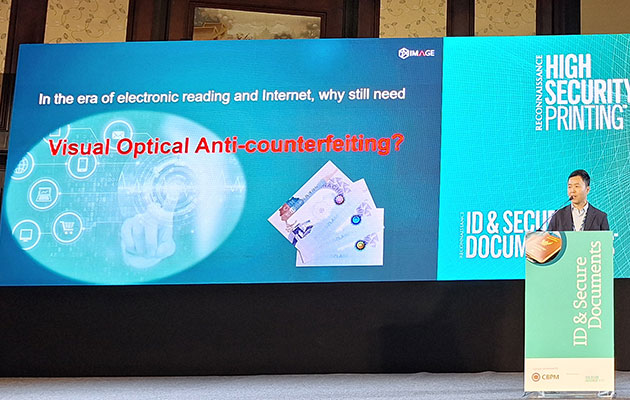

IMAGE TECH has specialized in optical anti-counterfeiting for over 30 years. With 60+ patents and multiple software copyrights, we provide secure solutions recognized worldwide.

We are:

- A trusted supplier for national ID documents and major conference credentials

- A pioneer in ink-free printing technology

- A recognized National High-Tech Enterprise and IOTA member

Our quality management system has also earned multiple awards, including the Blue Shield Cup, the Sun Cup Award, and the Packaging & Printing First Prize.

3. Provide Authorization and Documentation

Reputable manufacturers require official authorization before designing or producing stickers. If a supplier ignores this step, it signals poor security and weak confidentiality.

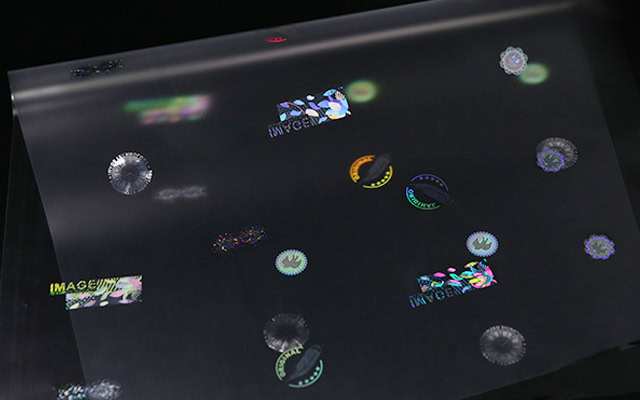

4. Finalize the Design Scheme

An effective design must:

- Provide real protection

- It will be extremely difficult to replicate

- Be partially recognizable by the public for quick verification

IMAGE TECH’s design team, led by award-winning experts, integrates brand elements such as logos into secure solutions. At the same time, we follow strict confidentiality protocols to protect brand data.

5. Sampling and Testing

Before mass production, samples are created and tested. Any problems should be corrected immediately to avoid costly rework.

6. Sign Contracts and Confidentiality Agreements

Contracts must clearly define responsibilities, delivery standards, and confidentiality rules to safeguard both parties.

7. Mass Production and Acceptance

Finally, after agreements are signed, large-scale production begins. Clients can request progress updates and must review all finished stickers before approval.

II. Common Pitfalls to Avoid

1. Do Not Prioritize Price Over Security

Cheaper holographic stickers often use generic templates or outdated methods. These are easy to counterfeit and ineffective for brand protection. Always balance cost with real security.

2. Plan Quantities Ahead of Time

Always order extra stickers to cover production loss or unexpected product demand. This ensures you won’t face shortages later.

III. Conclusion

Custom holographic stickers require advanced technology and careful design. By choosing a qualified manufacturer and tailoring solutions to your needs, stickers can become your brand’s first line of defense against counterfeiting.

With over 30 years of expertise, 60+ patents, and a proven track record of innovation, IMAGE TECH delivers secure and reliable holographic solutions to leading global brands.

👉 Ready to protect your brand with custom holographic stickers? Contact IMAGE TECH today for safer, smarter brand security.