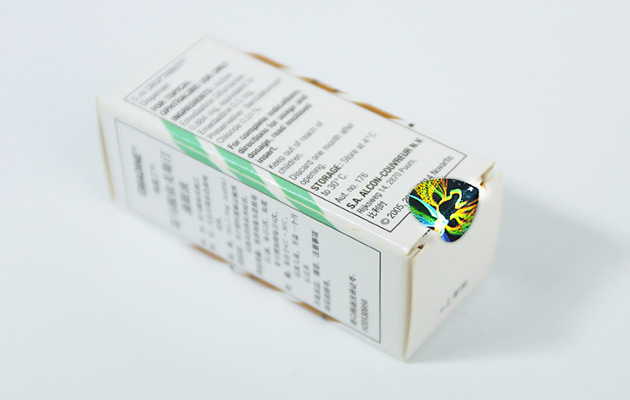

Tear tapes as an important package material, are being used more and more widely for various package solutions. There are different forms in the aspect of adhesive, width, bobbin size, and substrate material.

First, the adhesive type

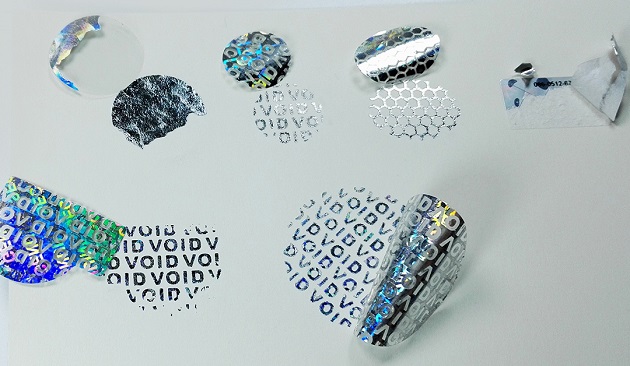

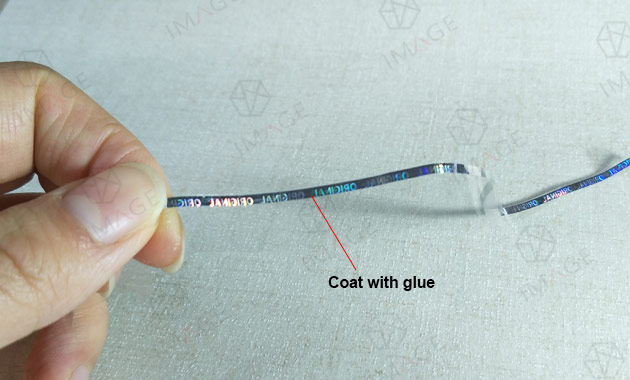

Some tear strip tapes are coated with adhesive, while others do not. In addition, in terms of adhesives, there are pressure-sensitive and hot melt adhesives. Usually, the self-adhesive is applied on one side of the tear tape, and the other side is coated with silicon to prevent the tape from sticking to each other.

Second, various widths for different applications

It ranges from 0.7mm to 8mm or wider. It’s easy to make wider tear tapes, but difficult to make narrow ones. We know that the tear tape is slit into narrow lines from wide web films. So the narrower, the higher requirement for the substrate material and the slitting machine, etc. Suzhou Image can make 0.7mm wide high precision tear tapes (we call them security threads), narrower for example 0.6mm, or even 0.4mm are under development.

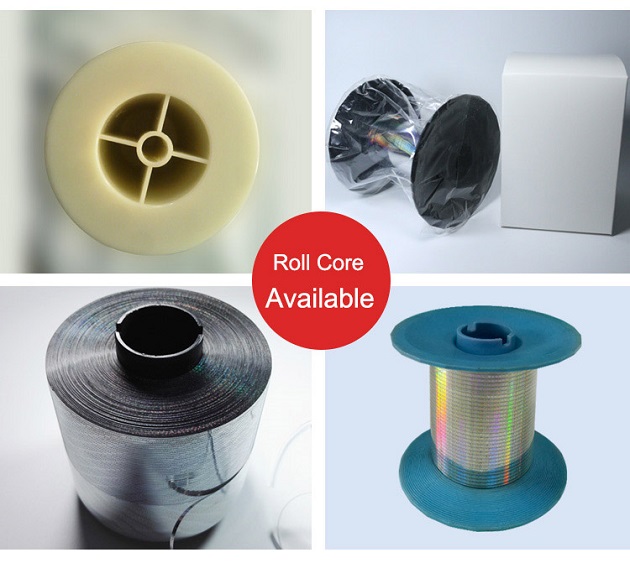

Third, bobbin size

For high-volume tear tape application, is usually in quite a big roll. The inner diameter can be 29mm, 3 inches, or 6 inches. Big bobbin saves time to change roll so improves production efficiency.

Forth, substrate material

Tear tapes are made of a kind of thin film, with certain tensile strength and other physical properties to get compatible with the final package processing.

Currently, Suzhou Image has two available substrates, PET(Polyethylene terephthalate), BOPP(Biaxially oriented polypropylene film), and MOPP. The film thickness ranges from 20 microns to 80 microns or higher.

PET (Polyethylene terephthalate), a very widely used plastic film, is a good choice for making tear strips. It’s suitable for soft package box applications, because of its low shrinkage and stable physical property.

BOPP (Biaxially oriented polypropylene film), compared with PET material, has higher shrinkage, is softer, and has lower tensile strength. Suitable for rigid package box application, and more cost-effective than PET.

MOPP, which is being more and more used for producing tear tapes in recent years, MOPP is stronger than PET, so it’s often applied for package opening with certain requirements of tensile strength, for example chewing gum, and rigid shipping envelopes. Regarding the cost, MOPP is the higher of the three.

We believe as the development of technology, there will be more optimized options for tear tapes, no matter the substrate materials, adhesive, and finishing process.

P.S: All the above technical standards are under Suzhou Image’s current product range, for details please refer to the sales contract and for more details please consult our technical support.