In today’s digital world, ID cards have become far more than tools for basic identification. They now play a vital role in enabling access, building trust, supporting transactions, and safeguarding security across interconnected systems.

However, identity fraud remains a serious problem. It causes about $300 billion in losses each year and puts people, companies, and governments at risk.

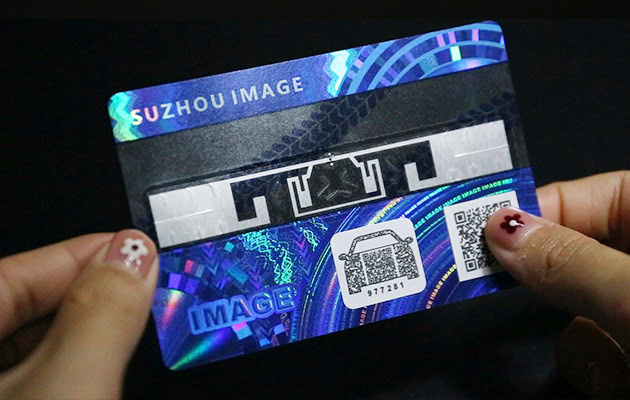

To fight this issue, many organizations are improving their ID card security. Among all the options, optical anti-counterfeiting technology stands out. Its clear visual effects and strong physical security make it a top choice for protecting identity.

Optical Security: Three Layers of Physical Protection for Trusted Identity

Optical anti-counterfeiting uses micro-nano structures to create effects that are nearly impossible to copy. Unlike barcodes or magnetic strips, this technology adds a visible, physical layer of protection.

Three Core Features of Optical Security Overlays

- Color-shifting patterns – These change with the viewing angle. They are easy to check but hard to fake.

- 3D embossed look – Microstructures create a deep, 3D visual effect.

- Hidden images or text – Some details are only visible under certain lights or with special tools.

Thanks to these features, security hologram overlays are now common in passports, ID cards, driver’s licenses, and company badges.

How to Make a Secure Optical ID Card

Creating a secure ID card involves three steps. Each step adds to the final card’s strength and durability.

Step 1: Card Pre-Production

First, card specifications such as layout, materials, and background patterns are confirmed with the client. Cards are then produced using large-scale card manufacturing machines. Popular materials include:

- PVC – A strong plastic used in most standard cards

- PC (polycarbonate) – Offers better heat and tamper resistance

- PETG – An eco-friendly choice with high strength

At this stage, fixed content such as company logos, design elements, or department names may also be pre-printed to speed up the later personalization. These pre-manufactured cards serve as the base for printing personalized data and applying the hologram overlay.

Step 2: Print Personalized Information

For applications requiring on-site personalization — such as visitor badges, conference passes, or staff cards — we provide dedicated card printers.

Users can print names, photos, serial numbers, QR codes, and more by simply operating from a connected computer.

The printer works with specialized color or monochrome ribbons to ensure high-quality, long-lasting output. This flexible solution is ideal for small batches or frequently changing print needs.

Step 3: Optical Overlay Lamination

The final and most critical step is applying the optical anti-counterfeiting overlay. A transparent film containing optical security elements is hot-laminated onto the card’s surface using a specialized laminator, sealing all printed information underneath.

This lamination process offers multiple benefits:

- Improved durability – Protects against scratches and fading

- Anti-tampering – If removed, the overlay shows clear signs of damage

- Data safety – Keeps personal information sealed inside

Modern laminators are fast and easy to use. They heat up instantly and work with film rolls that can cover around 500 cards. You can also connect the laminator to the printer for a smooth, one-step process.

What You Need to Get Started

To complete the entire ID card production process, the following equipment and materials are typically required:

- Pre-made blank cards

- ID card printer

- Printing ribbons (color or mono)

- Card laminator

- Optical overlay film (in rolls, laminate patch 500- 600 pcs per roll, ID transfer overlay 1000-1200 pcs per roll)

When combined, these tools help you produce secure cards quickly, with minimal effort.

A Safer Card, A Stronger Trust

Cards made with this process offer a high level of security and professionalism. The optical anti-counterfeiting features ensure immediate visual authentication and strong resistance against tampering or duplication.

This technology is widely applicable to standard CR80 cards, such as staff IDs, membership cards, transport cards, national IDs, and driver’s licenses, and serves various sectors, including government agencies, enterprises, and transport systems.

In an era of growing security demands, choosing an optical ID card solution isn’t just about better protection — it’s about safeguarding identity, ensuring trust, and reinforcing authority.

Need help designing a secure and customized ID card solution for your application? Contact us today — we’re here to assist!