Vehicle windshield labels play a key role in vehicle identification and security. They verify legal registration, insurance, road tax payment, and annual inspection compliance.

These labels are placed on the upper corners of the car glass window, allowing for quick viewing of vehicle information to confirm insurance or mechanical inspection validity.

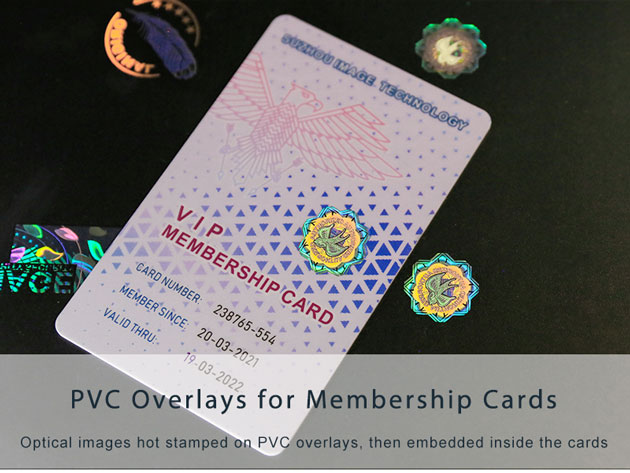

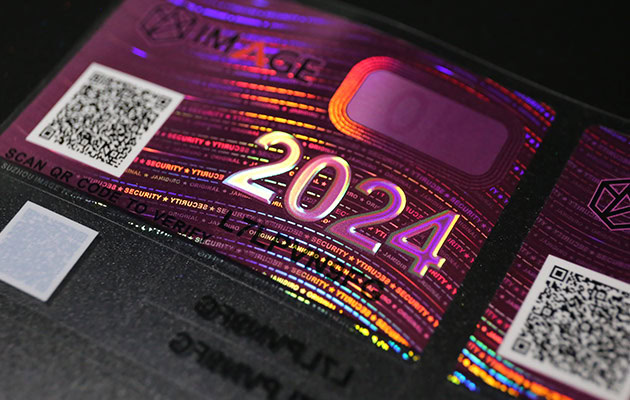

Despite their small size, car windshield labels contain detailed personalized information. They often have custom holographic logos, serial codes, QR codes, color printing, and expiration dates, making them highly secure.

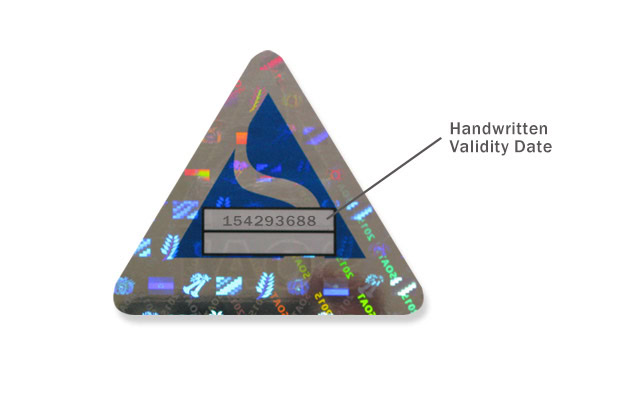

Many customers ask how we personalize the validity date information on these holographic windshield stickers. Today, let’s explore three common methods: handwritten dates, batch printing, and month punching. Each method has unique advantages for different needs.

Handwritten Validity Period

Handwriting the validity date is a traditional, flexible method. It’s usually done on-site with a special marker. This approach allows quick adjustments, ideal for small batches or specific needs.

Handwriting requires no complex equipment, allowing for unique notes or date changes. However, it demands durable markers that resist fading, smudging, or illegibility over time. For large volumes, handwritten labels may not be efficient.

Batch-Printed Validity Period

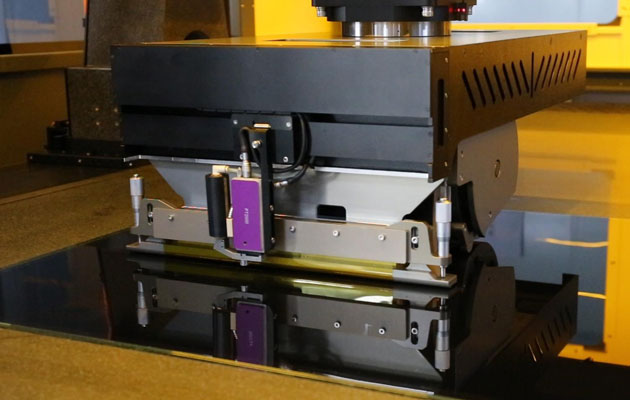

Batch printing is widely used in modern label production. With high-precision printers and software, designs—validity dates included—are printed directly on the label.

Batch printing’s main advantage is efficiency, producing large quantities quickly with accurate and durable results. It’s ideal for large-scale providers, ensuring consistency across car windscreen labels and easy management.

Bulk printed labels can integrate complex designs that enhance aesthetics and security. However, batch printing requires an initial investment in printers and software and may be less flexible for small batches.

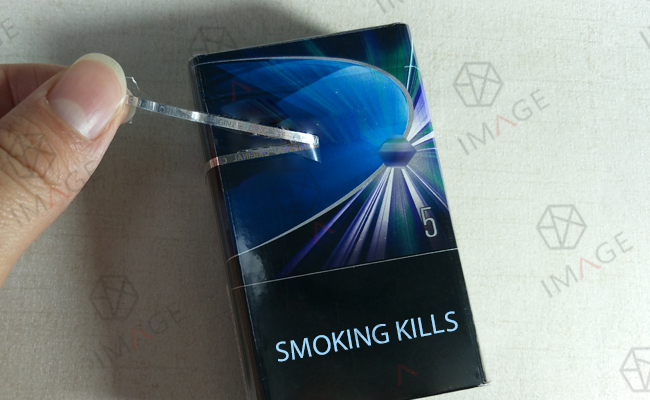

Validity Month Perforation

Month perforation is a simple yet effective method. Here, a hole is punched in the month of expiration, making the inspection status easy for authorities to verify.

This approach is recognizable and often used in car insurance labels. However, perforation requires precise equipment to avoid errors that could misrepresent the expiration date.

Each method—handwritten, batch printing, and perforation—has pros and cons for personalizing vehicle windscreen label validity. The best choice depends on factors like production scale, flexibility, cost, and durability. Careful consideration will ensure you choose the most suitable approach for your labeling needs.