In the printing and packaging industry, optical stamping foil has become a key material for both brand enhancement and anti-counterfeiting.

However, many companies face challenges when using it for the first time:

👉 The visual result does not meet expectations.

👉 The process is difficult to match with production lines.

👉 Storage and handling cause higher waste rates.

These issues can increase production costs and reduce competitiveness. Therefore, this article explains four key aspects — basic knowledge, process technology, storage, and applications — to help you fully understand IMAGE TECH’s optical stamping foil products and use them effectively.

1. Basic Knowledge

What is the difference between neon-color and hidden-color stamping foil?

The main difference lies in their visual effects and security principles.

Neon-Color (Transparent) Stamping Foil

This transparent foil uses nano-scale optical structures to create vivid color-shifting effects under reflected light. It can be stamped directly or layered over printed text and graphics to enhance brightness and color depth.

Because the color is produced by sub-wavelength nanostructures, it provides both high visual appeal and strong anti-counterfeiting performance.

Hidden-Color (Metalized) Stamping Foil

This foil has a metallic appearance that looks ordinary at first glance. However, when tilted or viewed from different angles, hidden iridescent colors appear.

It relies on nano-grating diffraction structures to achieve wide-angle optical effects and covert security features.

As a result, it is perfect for upgrading existing designs without changing the original layout, fitting today’s trend of “minimal yet luxurious” packaging.

2. Process and Technology

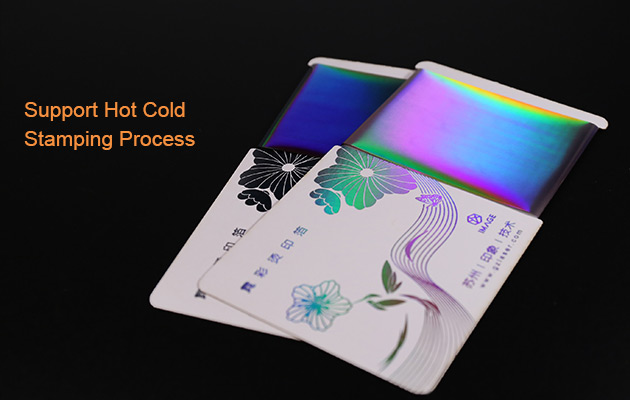

How to choose between hot stamping and cold stamping?

Both methods are supported by IMAGE TECH’s optical stamping foils.

- Hot stamping is ideal for small areas such as logos or symbols. It can be combined with embossing to create a tactile 3D effect.

- Cold stamping, on the other hand, is better for large graphics and wide-web applications. It is compatible with flexographic, offset, and screen printing processes.

When choosing a process, consider the substrate type, production cost, and target effect.

For instance, stamping after printing produces a shiny decorative look, while printing after stamping creates a layered and colorful visual result.

How to avoid adhesion failure or incomplete stamping?

These issues are usually related to the substrate and process setup.

To ensure stable results, focus on the following aspects:

- Surface tension – Ensure the substrate’s dyne level meets the standard. A low dyne level reduces adhesion.

- Surface smoothness – Avoid rough or uneven surfaces that can cause poor transfer or visible gaps.

- Process control – Adjust temperature, pressure, and dwell time according to the substrate type.

Hot stamping requires precise temperature control, while cold stamping depends on the correct adhesive formulation.

Additionally, performing small test runs before mass production can improve consistency and yield.

What should I prepare for custom-designed optical stamping foils?

To create a custom foil, you need to clarify three essential elements:

- Visual effects – Define the color-shifting angle for neon foils or the hidden color zone for metallic foils.

- Technical parameters – Specify width, thickness, and coating materials (such as aluminum or zinc sulfide).

- Design file – Provide a high-resolution artwork file to ensure accurate optical pattern reproduction.

In addition, a professional sampling test is recommended to confirm both visual and security performance before full production.

3. Storage Management

What are the recommended storage conditions?

Proper storage ensures the stability of foil performance.

Keep optical stamping foils at 15°C–35°C with humidity between 45%–70%.

Store them sealed and upright to prevent deformation or contamination.

Moreover, avoid storing foils near chemicals or under direct sunlight.

Before use, allow them to return to room temperature naturally.

For best quality and adhesive strength, use the foils within six months of production.

4. Application Fields

Where can optical stamping foils be used?

Optical stamping foils are widely used in:

• High-end packaging (alcohol, cosmetics, electronics)

• Labels and security seals

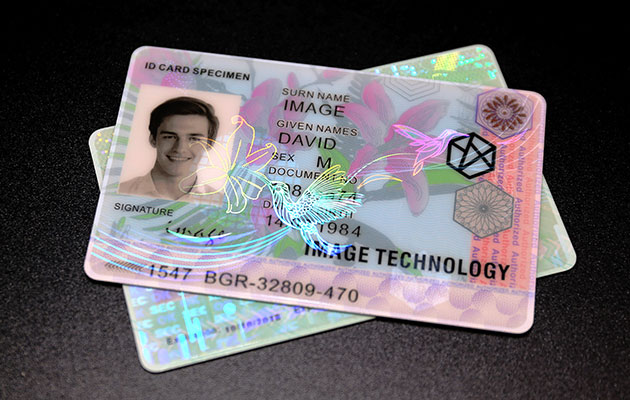

• Certificates, ID cards, and decorative prints

They not only enhance visual appeal but also integrate micro-nano optical security features to protect authenticity and brand image.

IMAGE TECH’s optical stamping foils offer dual benefits — decoration and protection.

They allow aesthetic upgrades without changing existing designs, helping brands achieve strong recognition and premium appeal.

Optical stamping foil is more than a decorative material — it is a fusion of optical technology, artistry, and security.

At IMAGE TECHNOLOGY, we continue to innovate in micro-nano optical manufacturing, achieving finer color control and wider material adaptability. Every foil we produce helps your brand shine — in both design and authenticity.