ID cards play a crucial role as a symbol of personal identity. Producing an ID card requires ensuring its authenticity and durability while incorporating anti-counterfeiting features.

This article will delve into the personalized printing process in ID card production, covering printing content, card materials, printing methods, and the application of optical heat laminate overlays.

The Importance of Personalization in ID Card Production

ID card production involves several steps: data collection, card production, personalized printing, and anti-counterfeiting measures.

Personalized printing is a vital step to ensure each ID card is unique. It involves recording and displaying personal information, directly affecting identity verification and security. It is closely related to financial investment, card issuance speed, and the security level of the ID card.

Contents of Personalized Printing on ID Cards

The main elements of personalized printing include:

Personal Photo

One of the most crucial elements of an ID card, enabling visual confirmation of the cardholder’s identity through photographing and printing their picture.

Personal Information: Key identity details such as name, gender, date of birth, ID number, and address.

Chip Encoding

Embedding a chip to store detailed personal information and biometric data, enhances security and convenience.

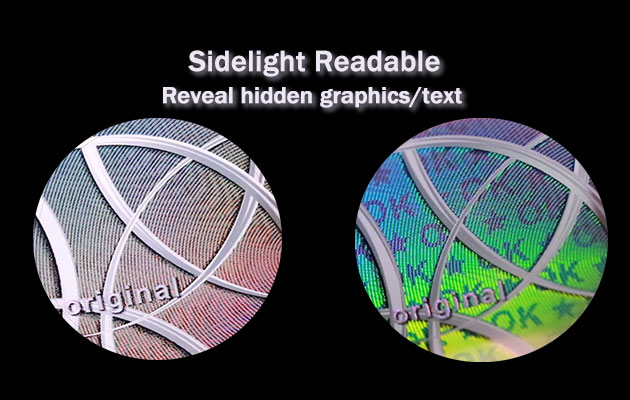

Anti-counterfeiting Marks

Adding watermarks, embedded holograms (optical security pattern embedded into card body), and other security features to make the ID card difficult to forge.

ID Card Materials and Personalized Printing Processing

The choice of card material and its properties are crucial for determining the personalization process, which is also influenced by the card issuance method. Different materials require different personalization methods and yield different results:

Common materials include PETG, PVC, Polycarbonate (PC), and Teslin (combined with heat lamination pouches, pouches can be laminated with Teslin cards to protect ID credentials from tampering ).

PETG (Polyethylene Terephthalate Glycol):

Personalization Methods: Suitable for thermal transfer, inkjet, and laser printing. PETG is eco-friendly and durable, making it ideal for long-term ID cards.

Pros and Cons: Eco-friendly and durable but relatively expensive.

PVC (Polyvinyl Chloride):

Personalization Methods: Suitable for thermal transfer and inkjet printing. PVC cards have smooth surfaces, making it easy to print images and text, but they are less durable than PETG

Pros and Cons: Low cost and easy to produce, but with appropriate durability.

Teslin (Special Synthetic Material):

Personalization Methods: Suitable for thermal transfer, inkjet, and laser printing. Teslin has excellent ink absorption and durability, widely used in various printing and security technologies.

Pros and Cons: Excellent printing results and durability, but higher material cost.

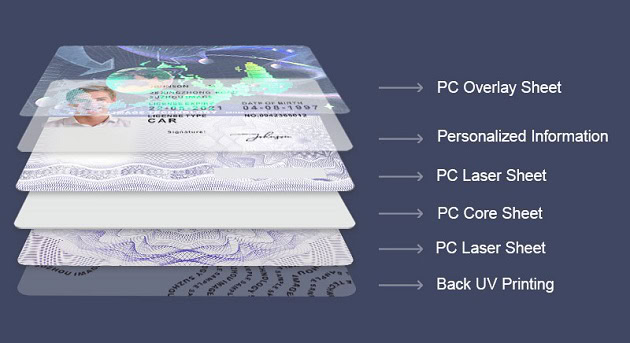

PC (Polycarbonate):

Personalization Methods: Suitable for laser printing and chip embedding. PC has high heat resistance and durability, making it an ideal material for high-security ID cards.

Pros and Cons: High strength and durability but expensive and complex to produce.

Different Material Personalization Processes

PETG and PVC: There are generally two personalization methods for these materials: one involves providing semi-finished roll materials for pre-printing and batch printing of personalized information, followed by lamination and card production.

The other involves pre-printing, lamination, and card production, with personalized information added using specialized ID card printers before card issuance.

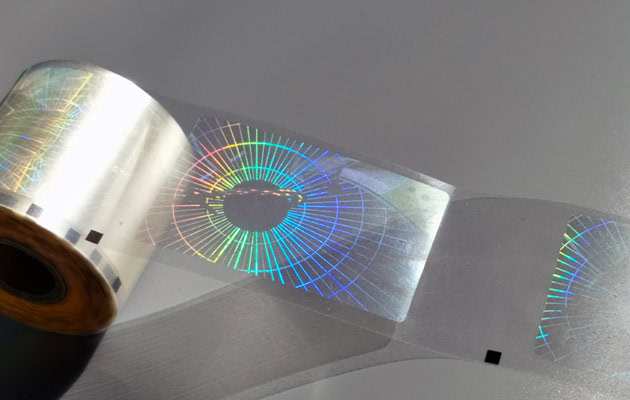

Sensitive documents may also be covered with a transparent or optical laminate patch after printing. Security laminates offer high anti-counterfeiting and scratch-resistant properties, protecting printed information from wear or tampering.

In addition to roll materials, Suzhou Image company provides pre-printed cards or finished cards with personalized information, depending on customer needs.

Teslin: Teslin combined with laminate pouches is used similarly to PVC and PETG, with roll materials for printing. Many customers also use single-sheet printing, such as printing multiple ID cards on an A4-sized sheet.

PC: Polycarbonate ID cards typically use laser printing for personalization, though batch printing like PVC and PETG is also possible. Laser personalization is preferred for higher anti-counterfeiting and tamper-resistance. The structure of a PC card is as follows:

Application of Optical Security Laminates in Personalized Printing

Optical security laminates are essential in ID card production, typically applied after printing personalized information. Their main functions include:

Protecting Personalized Information

Covering the card surface, optical laminate overlays protect printed information from wear, scratches, or tampering, extending the ID card’s lifespan.

Enhancing Anti-counterfeiting Features

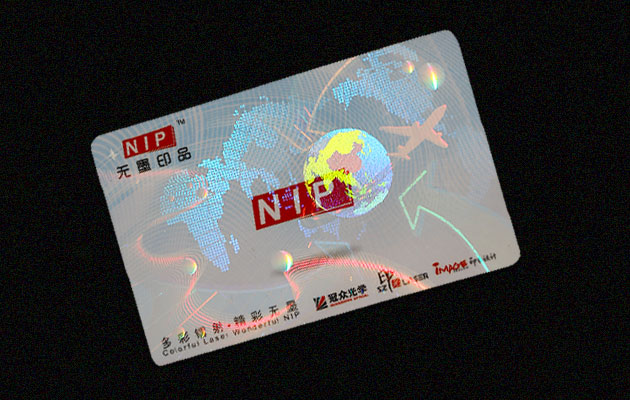

Adding holograms, watermarks, and other optical security elements makes the ID card more difficult to forge, improving security. Optical security laminates provide a layer of complex anti-counterfeiting technology that is hard to replicate even with advanced methods.

Improving Visual Appeal

Besides their security functions, security laminate overlays enhance the visual aesthetics of ID cards, making them more attractive and professional.

ID card production is a complex process where personalized printing plays a crucial role. The choice and processing of different materials have their advantages and disadvantages, and the application of IMAGE optical security laminates adds extra protection and anti-counterfeiting features.

As technology advances, personalized printing techniques in ID card production will continue to improve, providing society with more secure and reliable identity verification methods.