Recently, we received an inquiry regarding foil stamping materials used on official documents. This product is exactly what Suzhou Image Technology is good at. Today we will introduce it in detail.

When it comes to document hot stamping, we have to talk about the holographic hot stamping process, which can be roughly divided into positioning hot stamping and non-registration hot stamping.

Registered hot stamping foils have a continuously repeating optical image. Each optical pattern is equipped with a positioning cursor that can precisely position the optical image to the specified location.

Non-positioning hot stamping patterns are usually randomly distributed and can be combined with various printing processes to enhance packaging appeal and brand awareness.

Today we mainly introduce the application of holographic registration hot stamping on various documents.

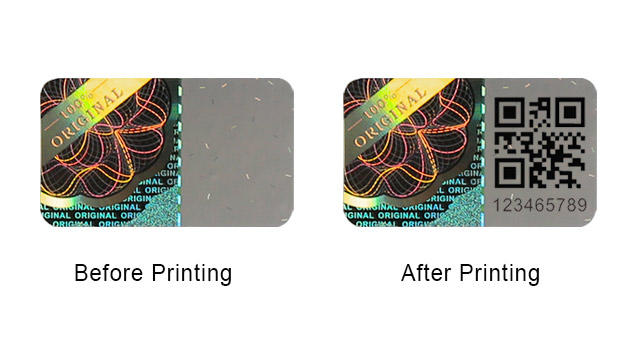

Registered hot stamping foil with good cutting, great hot stamping effect, and obvious security features. Compared with ordinary holographic hot stamping foil, it also has good high-temperature resistance after hot stamping and can withstand personalized information printed by a laser printing machine.

After hot stamping, the security hot stamping foil is integrated with the document. The foil cannot be lifted or transferred, otherwise obvious tampering will be left.

Widely used for various single-paper documents, government documents, book certificates, visas, university certificates, school certificates, quality assurance certificates, qualification certificates, etc. Most of them use this hot stamping method to identify and prevent forgery.

Specification:

| Size | Thickness | Inner Core | Packaging |

| Customized | 20 μm | 3 Inch | 3000 pcs/roll |

| Operational environment | Recommended hot stamping temperature is 200℃±5℃, pressure is 0.05kgf/㎡ |

| Preservation environment | Temperature 20°C – 30°C, Humidity 45%-60% |

| Executive standard | GB/T2790 GB10456-1989 |

| Common problems | 1, Uneven pressure causes incomplete hot stamping effect. 2, Hot stamping equipment register accuracy causes deviation. 3, Unclean environment causes bright spots or black spots. |

Key Quality Index (KQI):

| Temperature resistance/ thermal stability | 180°C/20s |

| Release force | 0.02N-0.03N/mm |

| Gauge deviation | 0.1mm |

| Slitting deviation | 0.2mm |

| Adhesion Test Procedure (ASTM) | 5B |

Due to the advancement of technology, the above indicators may be further improved and optimized, please contact our sales engineer to confirm.

The above index is the typical value but not guaranteed value, only for reference. The specific index is subject to the contract.

Holographic hot stamping requires an automatic high-speed positioning hot stamping machine to achieve large-scale production. And it has extremely high requirements for positioning accuracy.

Suzhou Image can control the accuracy within ±0.25mm. Anti-counterfeiting barriers have been raised in terms of anti-counterfeiting technology and hot stamping accuracy, making it difficult for counterfeiters to imitate due to technical difficulty, cost risks, and other factors.

If you have document anti-counterfeiting needs, please feel free to contact us. Our sales team will provide professional one-on-one customized solutions to ensure the security of your documents.