Recently, some customers have inquired about the PC overlay process and how we apply optical security images to PC overlays. This article will provide a detailed introduction.

Two Methods for Creating Optical Security Images on PC Overlay

Two main methods for creating optical security images on PC overlays are Register Hot Stamping and Direct UV Embossing.

Register Hot Stamping

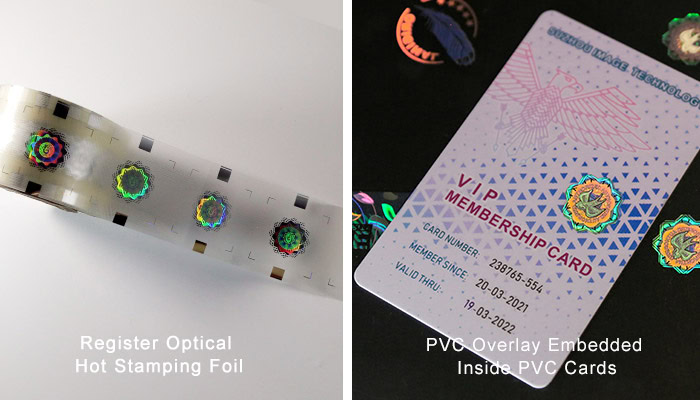

This method involves two steps: first, creating the optical security hot stamping material, we call it registered holographic hot stamping foil. And then using a hot stamping device to transfer optical images onto single-sheet PC overlays.

Create Hot Stamping Material: Holographic security patterns are first created on special hot stamping material.

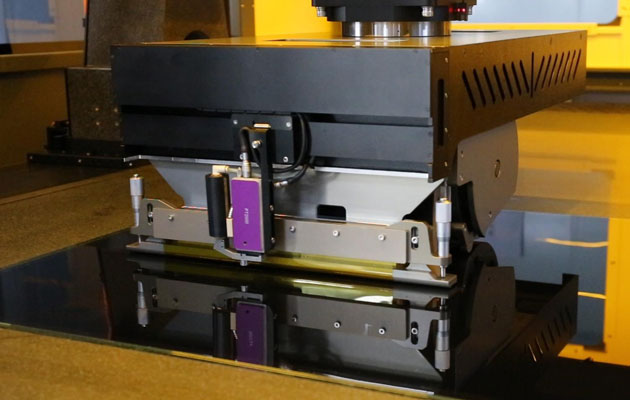

Hot Stamping: The prepared hot stamping hologram material is then transferred and stamped onto the PC overlay using specialized equipment, often in multiple rows simultaneously. This process is usually completed by card manufacturers and requires specific equipment tailored to different PC overlay specifications.

Direct UV Embossing

Direct UV embossing is another method for applying optical security images to PC overlays. This method uses UV curing technology to directly emboss the optical patterns onto PC rolls.

Embossing: Optical patterns are directly embossed onto the PC rolls using a UV embossing machine.

Curing: The patterns are permanently fixed onto the PC material through a UV curing process.

Advantages and Disadvantages of Positioning Hot Stamping and Direct UV Embossing

| Method | Advantages | Disadvantages |

| Register Hot Stamping | Precise positioning Printing, de-metalization, and other processes are directly done on the hot stamping material. Mature process, suitable for mass production. | Complex process. Requires additional hot stamping equipment and procedures. |

| UV Embossing | Direct embossing, fewer process steps. Fast production, suitable for continuous production. | Need to control UV curing time. Monitor PC material properties. |

Why Use Optical Hologram Patterns on PC Overlay?

After discussing the process, let’s explore why optical hologram patterns are added to PC overlays. Optical security patterns are created using advanced optical equipment, offering visually striking and highly secure features.

Integrating these holographic security patterns into PC (polycarbonate) overlays makes ID cards more secure, preventing forgery and unauthorized duplication. Additionally, these patterns enhance the visual appeal of the cards, making them more attractive and professional.

PC overlays with optical security patterns, also known as PC hologram overlays or PC embedded overlays, are commonly used in various government, election, financial, public, and enterprise ID card projects.

Including government-issued identity documents (passports and driver’s licenses), election cards, financial cards (bank cards), campus cards, and nurse cards.

Creating optical security patterns on PC overlays is a crucial step in enhancing ID card security, making them more attractive and identifiable. Both positioning hot stamping and direct UV embossing have their unique advantages, disadvantages, and suitable applications.

Understanding these methods can help businesses and government departments choose the most appropriate security solution. If you have any questions about PC card security, please contact our sales team, who will provide the best ID card solutions tailored to your project needs.