Register hologram foil stamping is also called hot stamping foil label or special pattern registered hot stamping, which is a new type of anti-counterfeiting technology, and has been widely used.

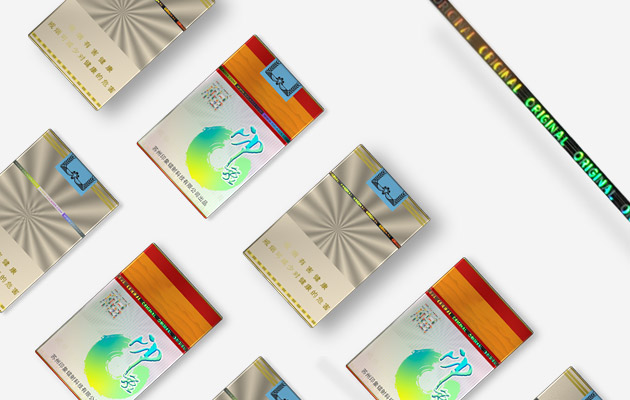

It’s mostly used for various event tickets, credit cards, visas, banknotes, bills, trademarks, tobacco and alcohol packaging, and important publishing for anti-counterfeiting.

Benefits of Using Registered Holographic Hot Stamping Foil

Registered holographic hot stamping foils are coated with a special adhesive coating to enable to transfer of the special holographic image on the surface using hot stamping machines without any difficulty. We manufacture it according to your needs so that you can either use it in registered form or continuous design.

Highlights:

- Eye-catching holographic color combinations.

- Strong visual appeal that makes it easier to verify the brand

- Designed with multiple security features, hard to duplicate.

- Almost impossible to lift after hot stamping, preventing tampering.

- Holographic image transfers by heat on different surfaces for both authentication & decoration.

Production Process of Fixed Position Holographic Hot Stamping Mould

The production process of the fixed position holographic hot stamping mold is the same as that of the ordinary flat hot stamping and the concave-convex hot stamping mold.

It must use special laser aluminum foil and an advanced registration detection system, which determines that holographic positioning hot stamping has stricter and higher requirements for hot stamping materials and hot stamping machine performance than other hot stamping processes.

The adjustment of the registered sensor

During the holographic registered hot stamping, the adjustment of the detection electric eye (sensor) is the most important step. The correct adjustment method is: you must first observe the reaction state of the detection sensor when the machine is running, and then make corresponding adjustments, to ensure that the reaction of the detection sensor is sensitive and accurate, and cannot refer to the response state of the detection sensor in a “clean” state.

About the seam line of hologram hot stamping foil

Since most of the holographic patterns on the stamping foil are arranged independently and intermittently, a seam line will appear every certain distance on the stamping foil in operation.

If the gap distance of the holographic positioning pattern can’t be properly controlled, there will be a seam line, resulting in defective products.

Therefore, controlling the seam-skipping procedure of holographic hot stamping foil is also an important factor in the production of hot stamping products.

Other Additional Tips

During the hot stamping process, sometimes some issues, such as printing products can’t do hot stamping because of UV coating.

This is caused by the incompatibility between hot stamping foil and UV varnish. At this time, it is necessary to adopt the method of first hot stamping and then UV coating.

If the product that is ready to do printing needs to be processed by laser embossing transfer, you had better do the laser embossing transfer first and then hot stamping.

If you want to learn more about the hologram positioning foil stamping process, pay attention to our website, and we will continue to introduce other types of hot stamping processes in the future.