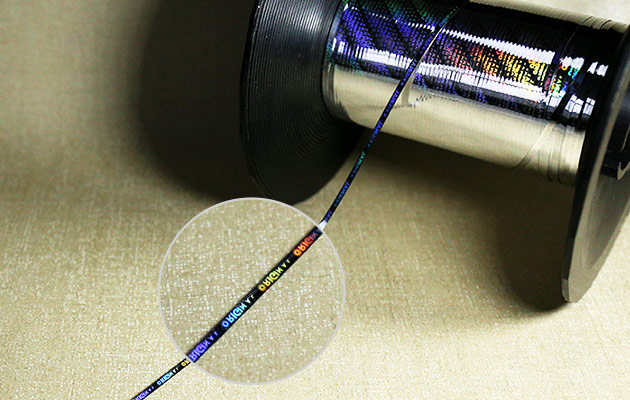

Recently, customers have been asking frequently about ID card lamination. Why our ID card hologram overlays can’t be adapted to their existing equipment? Instead, they have to buy another brand of laminators. Since different brands of laminating equipment are equipped with corresponding reels and chips, and the layout of each device is different, compatible reels and chips are not available on the market.

Another reason is that agents of the same brand in different regions are affected by chips, and the consumables used are not universal. So using special equipment, we can get the layout of the equipment and buy the reels and chips matched to the brand.

If the customer can provide the layout by himself, including the reels and chips of the equipment, the customer can also purchase it themselves. This way, it can be ensured that holographic varnishes and over laminate patches purchased from us can be used normally.

Some Common Problems During the Lamination

Some problems may occur during the lamination process, such as cards that have a sort of dog-eared look, some surface defects, position deviations, etc. These can be adjusted through parameters. We can adjust its lamination speed, lamination temperature, and left and right position.

In addition to this, if you use PVC cards, the edges of the card may curl due to heat during the lamination process. The solution is to adjust the lamination speed and lower the temperature to improve this.

Our laminators can perform single-sided (front or back) and double-sided lamination. Cards can be turned over automatically inside the machine.