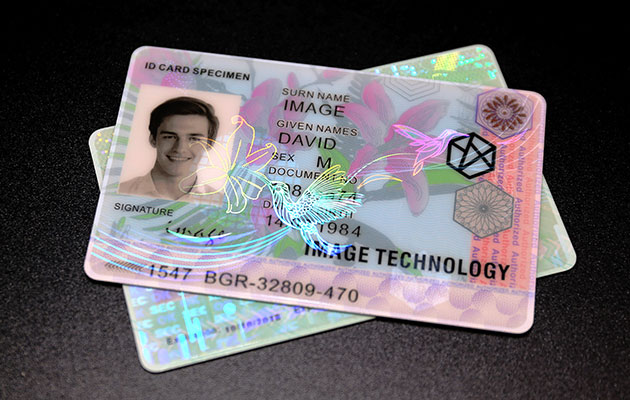

Recently, Image Technology has received a high volume of inquiries and sample requests for its newly launched optical stamping foils, which integrate multiple visual effects with advanced optical anti-counterfeiting technologies.

According to customer feedback, application fields are highly diverse, covering packaging, anti-counterfeiting labels, paper certificates, and security documents, as well as brand decoration.

Before arranging sample delivery and quotation, we usually confirm several key points with our customers. This helps us clearly understand actual application needs, assess whether our optical stamping foils are suitable, and ultimately reduce trial-and-error costs while improving testing success rates.

Based on real project experience, this article outlines the essential considerations to confirm before sampling.

In previous articles, we have introduced our optical stamping foil types—such as Neon-Color and Hidden-Color—along with integrated technologies including multi-channel micro text, side-light reveal, and optical magnetic image effects.

Here, we focus on practical application guidance to support smoother communication and more efficient testing.

1. Key Information to Confirm in Advance

1) Stamping substrate

First, please confirm the material onto which the optical stamping foil will be applied.

At present, our optical stamping foils are mainly used on:

- Paper-based packaging materials

- Anti-counterfeiting label paper

- Security paper documents and certificates

- Teslin, PVC card, and PC embedded overlay

For other substrates—such as glass, leather, plastics, or composite materials—additional testing is usually required.

Surface characteristics, including flatness, texture, gloss, or matte finish, can significantly affect stamping results and optical performance.

2) Required foil width

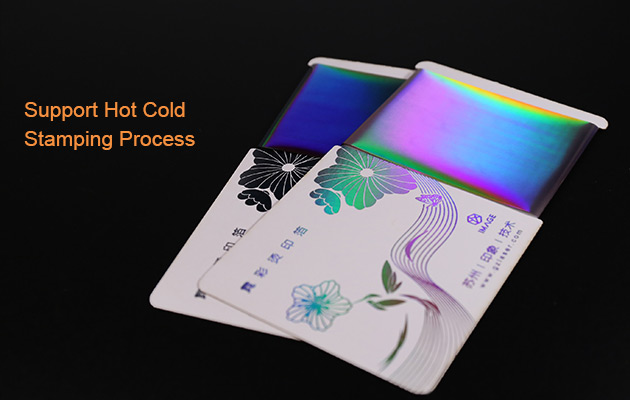

Different stamping processes require different foil widths.

- Hot stamping: typically used for localized or small-area designs

- Cold stamping: better suited for large-area, continuous, or full-coverage applications

The industry-standard foil width is 640 mm, which is also our regular stock specification. If a special width is required, please inform us in advance so that feasibility can be evaluated.

3) Stamping method and format

Please clarify the following details as clearly as possible:

- Positioned stamping, full-area stamping, or registered stamping foil labels

- Cold stamping or hot stamping process

- Manual stamping or automatic stamping equipment

These factors directly influence foil structure design, process compatibility, and testing methods.

4) Testing requirements or evaluation criteria

Some customers have specific testing objectives, such as:

- Abrasion resistance or adhesion performance

- Verification of particular optical security features

- Compatibility with existing production equipment or processes

Sharing these requirements in advance enables us to recommend the most suitable foil solution more accurately and efficiently.

2. Sample Supply Information

Currently, our IMAGE TECH company supplies optical stamping foil test samples in the following standard format: 640 mm × 60 mm per roll.

As stamping tests require machine operation, samples are provided in roll form to support realistic production testing.

By confirming the above information in advance, both parties can significantly reduce testing costs, streamline communication, and improve efficiency throughout the sampling, testing, and quotation stages.

If you have specific application scenarios or testing requirements, please feel free to contact us. Suzhou Image Technology is committed to providing tailored optical anti-counterfeiting solutions for security documents and commercial brands.