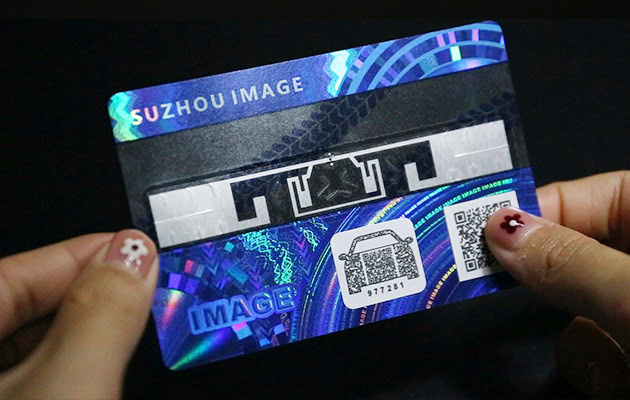

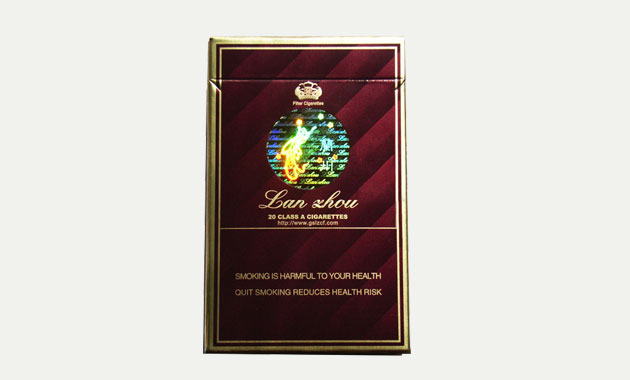

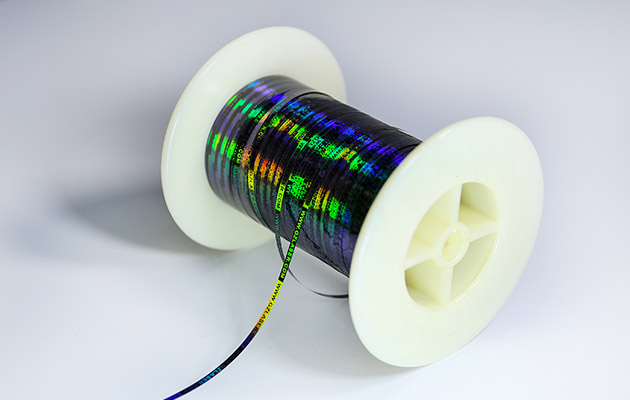

Optical hologram labels are vital in protecting brands and helping consumers verify product authenticity. As a result, they are widely used across industries and have become an essential tool for brand protection.

However, the products needing anti-counterfeiting protection come in many different materials. So, how can brands ensure that holographic labels stick well and last long on various surfaces?

This guide explains which materials holographic labels can be applied to, what adhesive technologies are used, and how different application scenarios affect performance. It also highlights why these labels are so adaptable and widely trusted.

🧩 Why Adhesive Matters in Holographic Labels

The performance of a holographic label largely depends on one important element: adhesive. The type of adhesive determines how well the label sticks, how long it lasts, and whether it resists environmental stress.

When choosing an adhesive, brands must consider several key factors:

- Initial tack and long-term adhesion

- Resistance to temperature, UV light, and chemicals

- Environmental friendliness

- Clean removability without residue

Choosing the right adhesive helps ensure the label performs its security function while staying tamper-evident throughout the product’s lifecycle.

🔍 Common Adhesive Types and Their Characteristics

1. Water-Based Adhesives

Water-based adhesives are eco-friendly and easy to clean. For example, removable versions leave no residue, making them ideal for food and pharmaceutical packaging.

2. Solvent-Based Adhesives

These adhesives offer more lasting adhesion and quick curing. They work well on plastic, metal, glass, and paper, which makes them a popular all-around solution.

3. Hot Melt Adhesives

Hot melts are solid at room temperature and melt when heated. As they cool, they form strong, fast-setting bonds—perfect for high-speed production lines.

4. UV-Curing Adhesives

These adhesives harden quickly under ultraviolet light and offer excellent strength, chemical resistance, and heat stability. They are often used in electronics and other precise applications.

For optical hologram labels, water-based pressure-sensitive adhesives and solvent-based adhesives are the most commonly used types. Water-based adhesives offer strong initial tack, while solvent-based adhesives provide more durable, long-term adhesion.

When selecting an adhesive, it’s important to consider both the label’s specific application requirements and the environmental conditions in which it will be used. For instance, labels exposed to high or low temperatures, varying humidity levels, or outdoor conditions may require specialized adhesive formulations.

Additionally, the type of surface material—whether it’s plastic, paper, metal, or wood—directly affects how well an adhesive performs.

Therefore, always evaluate both the application environment and the label material to ensure the adhesive delivers optimal bonding strength and long-lasting security.

🧱 Material Compatibility of Optical Labels

At Image Technology, we’ve engineered our optical labels to perform well not only in terms of security but also in terms of material compatibility. Whether it’s plastic or wood, our labels maintain strong adhesion and visual appeal.

Let’s explore how our labels interact with different materials:

🧴 Plastic Surfaces

Plastic is common in consumer goods because it’s lightweight and easy to mold. Our labels adhere strongly to both flat and curved plastic surfaces, keeping their shape and clarity.

🥫 Metal Surfaces

Metal packaging is durable and often sealed—think of food cans or spray bottles. Our security labels stick firmly to these smooth surfaces and stay put even under challenging conditions.

🍾 Glass Surfaces

Glass is elegant and commonly used for cosmetics and alcohol. Our labels add visual appeal and tamper-proof protection without affecting the clarity of the packaging.

🧼 Ceramic Surfaces

Ceramics are used in niche sectors like luxury beauty and pharma. They’re smooth and heat-resistant. Our adhesives handle them with ease, ensuring a secure bond.

📦 Paper Surfaces

Paper is everywhere, especially in sustainable packaging. Our labels pair well with paperboard boxes and sleeves, offering both eco-friendliness and visual integrity.

🎁 Wood Surfaces

Wood adds a premium feel, often used in packaging for tea, wine, and gifts. Because wood is porous, we fine-tune adhesive viscosity to ensure deep penetration and strong, long-lasting bonding.

🎯 Tailored Solutions for Every Industry

With expertise in both material science and optical security, Image Technology offers adhesive solutions that are compatible across various surfaces and industries.

We evaluate real-world conditions—like heat, moisture, and chemical exposure—to develop adhesives that ensure your labels stay secure and functional at all times.

More than just sticking, we aim to provide integrated solutions that combine anti-counterfeiting innovation with material engineering. Our approach helps brands achieve better protection while maintaining design flexibility and cost-efficiency.

Need help choosing the best optical hologram label for your packaging material?

👉 Contact our experts for custom recommendations tailored to your industry.