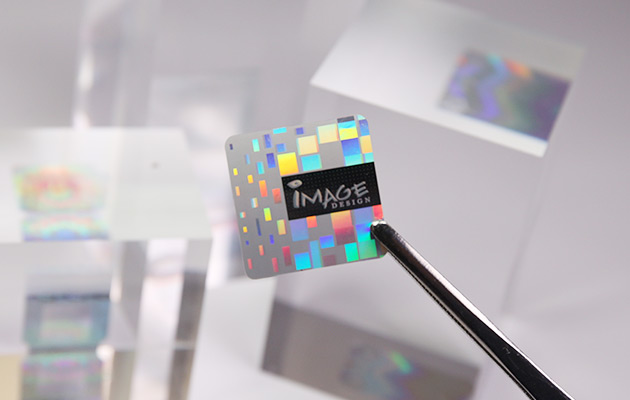

Hologram patch film is a transparent film specially used for surface protection of standard-size cards (CR80 ID cards). Because it is pre-cut and lined on a release film, it is also called a pre-cut hologram.

The patch film is one of many ID hologram overlays. It has good scratch-resistant, wear-resistant, waterproof, and anti-counterfeiting characteristics. Therefore, it is a very popular form of holographic lamination for national ID cards, driver’s licenses, and personal documents.

Basic Parameter about ID Card Patch Film

Suzhou Image provides PET material ID card patch film, which is suitable for PVC and PETG cards.

| Patch film | Release film | Size | Inner core | Packaging specification |

| 16um PET | 50um | 82.6mm*51mm | 3inch or customized | 600 pcs/roll |

Top 5 Benefits of Using Hologram Patch Overlay for ID Cards.

The patch overlay has high transparency and has certain plasticity, wear resistance, waterproofness, and antifouling properties. Incorporating holographic technology can increase visual appeal and anti-counterfeiting properties.

At present, Suzhou Image mainly develops the application of holographic patch film in various card fields. The following is a detailed description of the advantages of hologram patch overlay in the field of card application.

Visual appealing.

Holographic technology can create a unique three-dimensional and dynamic effect, making the card more vivid and eye-catching. This visual effect not only improves the aesthetics of the card but also improves the visual security of the card.

Anti-counterfeiting.

The design and production process of holographic images is complex and difficult to imitate and copy. Even if you want to copy, you need high-precision dot matrix equipment and professionally trained technicians to operate it. Even so, it’s difficult to achieve 100% similarity without the original hologram master. This enhances the security and anti-counterfeiting properties of the card.

Durability.

The holographic patch is over-laminated on the card surface, has a certain wear resistance, and can effectively protect the card surface from scratching and wear.

This wear resistance can prolong the service life of the card, and then improve the quality and reliability of the card.

Waterproof and stain-proof.

The application of patch film can effectively prevent moisture, stains, and dirt from invading the card surface. This feature not only improves the appearance quality of the card, but also reduces the workload of cleaning and maintenance and improves the user experience.

Strong plasticity.

This plasticity ensures a smooth card lamination process. The film bonds closely to the surface of the card, making it difficult to produce bubbles, wrinkles, and residual glue. Improved the appearance quality and beauty of the card.

These advantages make holographic patches an ideal choice in the card field, which can improve card security, quality, and user experience. Meet the high security and multi-functional needs of the card.

What cards can the Hologram patch film be used on?

Compatible with a variety of cards, the hologram patch film increases the durability and physical and visual security of ID cards.

ID cards.

As the most important proof of identity, identity documents require a high degree of security and durability. Holographic laminated patches protect personal data on identity documents from forgery and tampering, as well as personal information from wear and tear.

Driver license.

Similar to an ID card, a driver’s license is also an important personal driving credential. The driver’s license contains personal information, including name and document number, etc.

The holographic patch film is designed with a variety of overt and covert security features, which can form a protective layer for the driver’s license, and prevent the driver’s license from being forged.

Hologram driver’s licenses fundamentally reduce the possibility of illegal drivers on the road and reduce the occurrence of traffic accidents.

Student ID cards.

Student cards can be used for a variety of purposes, such as borrowing books and entering designated areas. To improve the security of the student card, holograms are usually added to the student card to ensure the authenticity and security of the student card.

Employee ID cards.

Corporate security cannot be ignored. Issuing each department its own unique holographic ID card prevents unauthorized access. This way prevents information theft and loss of company and personal property.

VIP membership card.

Used to identify members and enjoy related benefits.

Venue access.

Some occasions require special passes, such as airports, stadiums, conferences, etc.

Passes with holographic images are easy to identify and difficult to forge, making it easy for venue inspectors to quickly identify and prevent illegal personnel from entering the venue.

How to laminate the hologram patch on the ID cards?

The whole lamination process needs a special laminator. We have made a video to help you better understand its lamination principle.

How to solve some common problems during the ID card lamination process?

Bubbles: Bubbles are a common problem during lamination, usually because the film does not fully adhere to the surface of the card. It is recommended to ensure that the card surface is clean and smooth before lamination.

Wrinkling: Wrinkling occurs when the ID is attached, usually due to uneven stretching of the patch film or improper operation. In addition to making sure the surface is clean and smooth, avoid overstretching the film material.

Residue: Residue or stains may remain after application, affecting appearance and cleanliness. It is best to use professional solvents to remove residue before lamination to ensure the surface is clean and dust-free.

Card curling after lamination: Some customers come across cards that become curling while lamination. This is because of the heat, we need to set the lamination speed and temperature to get a lower temperature to improve this.

To solve the problems that occur during the card lamination process, it is necessary to comprehensively consider many factors such as card preprocessing, lamination environment, parameter settings, and operating skills to ensure the quality and stability of the whole lamination.

If you have any questions about the ID card patch film, please contact our sales and they will give you some suggestions.