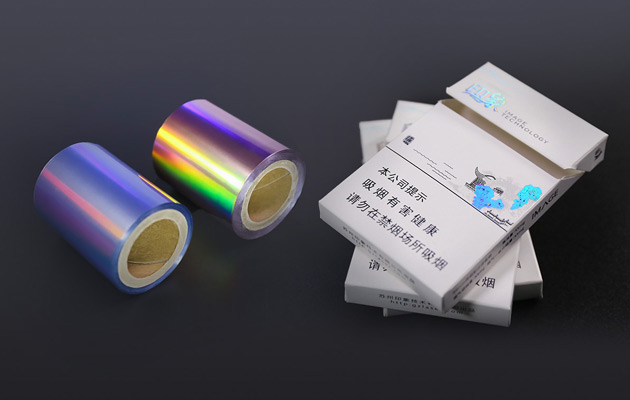

Custom registered stamping foil (also known as fixed-position stamping foil) is widely used in high-security applications where precise positioning and reliable visual authentication are essential.

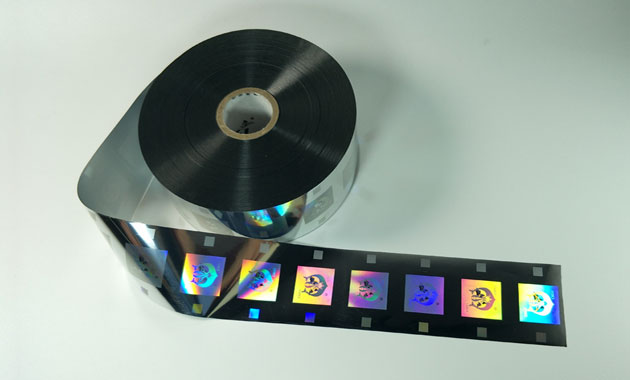

Unlike standard hot stamping foil, optical stamping foil with fixed positioning requires full customization. Each project includes dedicated optical security design and the use of eye marks (registration marks) to enable accurate machine recognition during the stamping process.

As a result, defining key requirements at an early stage helps customers achieve stable performance, controlled costs, and long-term anti-counterfeiting value.

What Is Custom Registered Stamping Foil?

Custom registered stamping foil is an optical security foil applied at a predefined and fixed position on the substrate. During stamping, the image must align precisely with printed graphics, variable data, or structural elements. Therefore, the process relies on accurate registration control using eye marks (registration marks).

Typical application areas include:

- ID cards and government-sensitive documents

- Certificates and licenses

- Tax stamps, alcohol, and tobacco labels

- Brand protection and secure packaging

Thanks to its high positioning accuracy and complex optical structures, this type of stamping foil significantly increases the difficulty of counterfeiting and serves as a high-level security solution.

Step One: Clearly Define Your Customization Requirements

To produce a qualified custom registered stamping foil, a clear and complete requirement definition comes first.

Key information includes:

- Whether a custom optical security pattern is required

- Availability of original artwork or design elements

- Application scenario and usage environment

- Required stamping image size

- Substrate material to be stamped

These factors directly influence optical structure design, registration tolerance control, and foil layout.

Consequently, clearer communication at the early stage leads to more stable and reliable optical stamping foil performance.

Minimum Order Quantity for Custom Positioned Stamping Foil

The standard minimum order quantity for custom fixed-position stamping foil is 500,000 pieces (500K impressions).

This requirement is practical rather than arbitrary.

In production, the process includes:

- Machine setup, installation, and calibration

- Registration testing and fine adjustment using eye marks on the production line

- Trial runs that consume several hundred meters of material to achieve stable positioning accuracy

Even when customers request smaller quantities—such as 100,000 impressions—the same setup, testing, and commissioning steps still apply. Therefore, a minimum production volume ensures both technical feasibility and cost efficiency.

For this reason, custom registered stamping foil works best for long-term projects, ID documents, and large-scale brand protection programs.

How Is Pricing Calculated for Optical Registered Stamping Foil?

The price of custom optical registered stamping foil does not depend solely on size.

Instead, accurate pricing considers several technical factors, including:

- Substrate material type

- Optical security design complexity

- Artwork layout, eye mark (registration mark) position, and repeat pitch

- Registration accuracy requirements and alignment tolerance

When customers provide complete technical information, suppliers can offer more precise quotations and avoid cost deviations or performance mismatches later in the project.

Standard Customization Process for Optical Fixed-Position Stamping Foil

The customization of fixed-position optical stamping foil follows a clear and controlled workflow:

- Requirement confirmation – The client provides application details or artwork

- Optical security design – The technical team develops and confirms the optical solution

- Tooling development – Dedicated embossing tools and masters are produced

- Mass production – Manufacturing proceeds under strict quality control

- Inspection and delivery – Final verification takes place before shipment

Each step plays a critical role in ensuring registration accuracy, visual consistency, and product reliability.

Why Precision Matters in Anti-Counterfeiting Solutions

As counterfeiting techniques continue to evolve, security solutions must become more precise and more application-specific.

When designed and implemented correctly, custom registered stamping foil becomes more than a material. It serves as a reliable visual and technical safeguard that protects documents, products, and brand value.

Ultimately, only by defining requirements clearly and understanding the full process can optical registered stamping foil deliver its intended security performance.

Work with a Professional Optical Security Partner

With long-term experience in optical anti-counterfeiting technologies, Image Technology delivers custom registered stamping foil solutions tailored to real-world applications.

If you have any questions about custom registered stamping foil or optical fixed-position stamping foil, our technical team is ready to support your project—from design to final delivery.