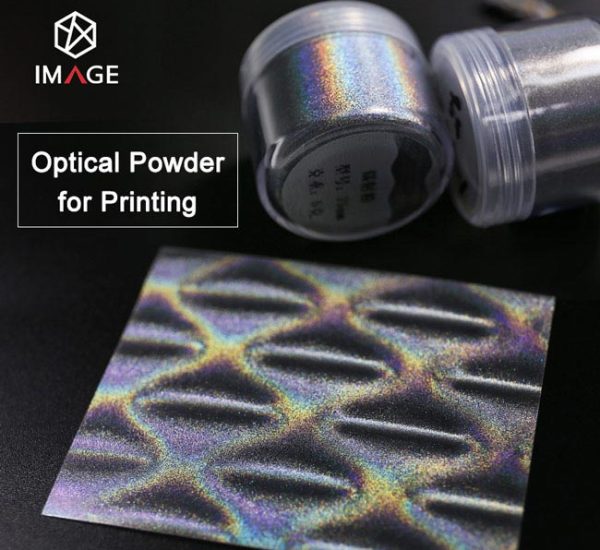

Dissolution sequence: optical diffraction powder infiltration → transfer in resin ink.

When used in the organic solvent system, the powder can be soaked with the organic solvent (such as ester, ketone, etc.) fused with the system. The soaking time shall not be less than 2 hours, and it shall be fully stirred to improve the dispersion. The wetted optical structural color powder is evenly added into the resin ink in proportion, and suitable dispersant or coupling agent is allowed to be added. It is recommended to use “propylene glycol or propylene glycol methyl ether” as a wetting agent, and its slurry is effective after being sealed and stored at room temperature for 6 months.

When used in an aqueous system, it is recommended to infiltrate the powder with purified water and stir it fully, so that the powder can be more evenly dispersed, and the soaking time shall not be less than 2 hours. The wetted powder is added to the resin ink in proportion, allowing the addition of appropriate dispersant or coupling agent.

In actual use, if ethanol is needed as the diluent, it is recommended to use it when the concentration is less than 10%, and do not store the solution containing ethanol for a long time.

When used in an aqueous resin system, avoid wetting the powder with solvents such as ethanol, organic ester, ketone, and toluene, and do not use tap water as the wetting agent.

The PH value of the solution containing optical diffraction powder is recommended to be about 7 to avoid acid-base erosion.